Material mutations and waste transformations

At Anchor, we are curious about waste and how we can re-imagine and reposition it as a material resource.

Projects / 01.2022

Since 2017, Anchor has run an on-going research and development (R&D) project identifying waste materials from our making process and those of our partners. We explore how these materials can be reimagined through the lens of a ceramic practice back into the world of material opportunity.

PAPER CLAY FROM OFFICE WASTE

When clay is fired in the kiln the temperature it reaches is high enough to burn off (or out) all organic material. By adding shredded strips of paper, generated by Anchor’s office and packaging activity, we were able to create very strong clay slabs that, in the kiln, transform into porous and light panels, and feature a unique textural finish.

SINK SLIP FROM GLAZE WASTE

The sink in our studio is outfitted with a trap that collects clay and glaze particles, thus preventing them from going down the drain and into our local watershed. We were curious what properties this collected ‘sink slop’ might have if fired in the kiln. The result was a very brown foamy mound. Often when we run exploratory tests, there’s typically a next step or opportunity present that we see in the material - this however was an exception and we didn’t do any further testing on this material.

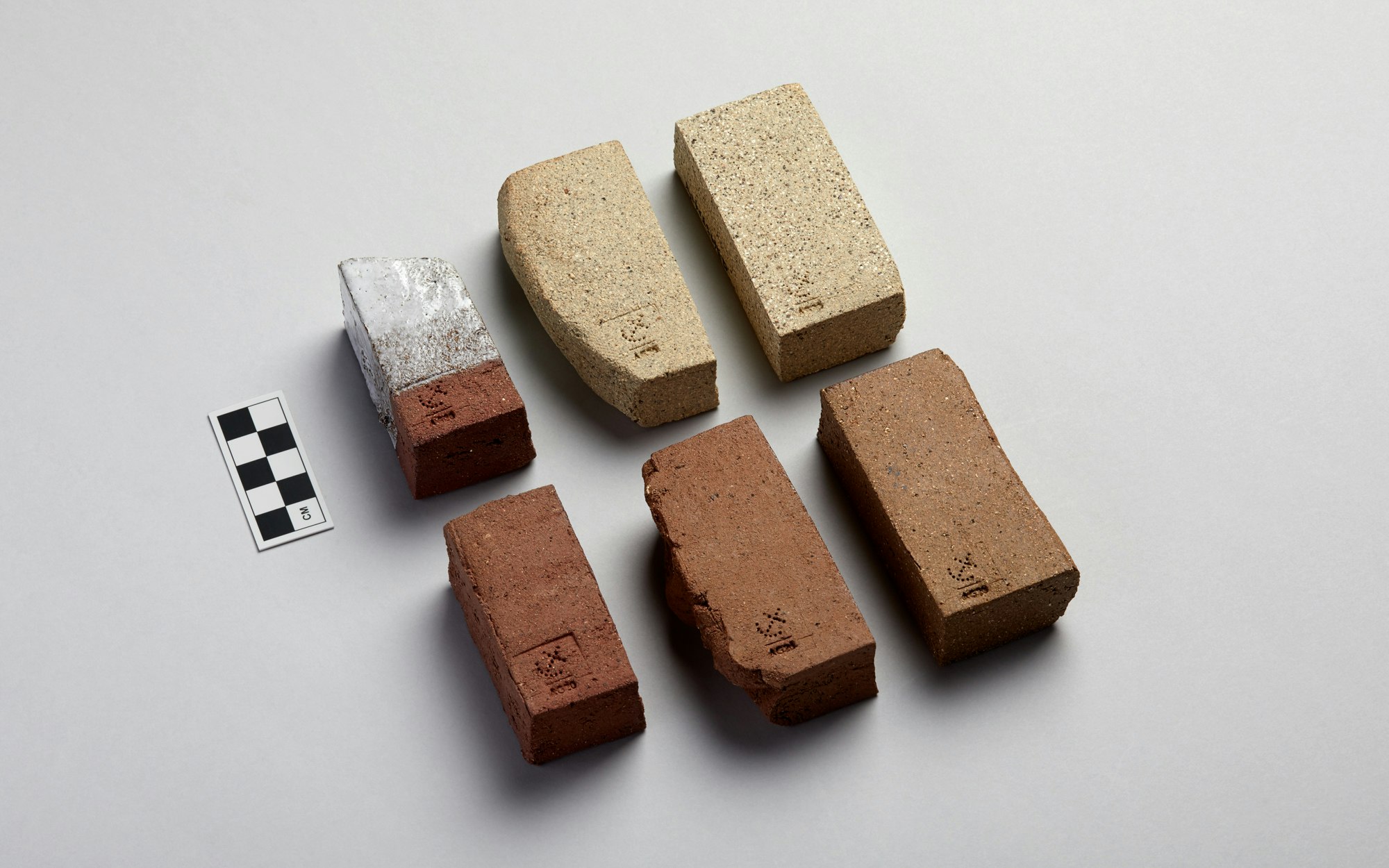

BRICK GROG FROM CONSTRUCTION WASTE

Anchor products are often delivered directly to the building site for installation on a project. Construction and building activity generates a significant amount of waste - one of these waste streams comes from broken or unused bricks. We saw an opportunity to rework waste from these bricks into an aggregate that we could use to create a toothy surface to the clay and improve the strength of the clay in the kiln. In order to use the brick material we first had to develop a process for breaking the material down and sorting it into different mesh sizes to allow for a greater control when mixing it to clay - the results show how the texture of the clay body can be adapted with a very fine grain size of brick waste.

STUDIO PROCESS CLAY BODY FROM WASTE CLAY

For the most part our working process allows us to minimise waste by reclaiming the vast majority of clay off-cuts, however there are times, such as when we need to change over the clay in our equipment, that necessitate the creation of a contaminated clay that cannot be reused and becomes a form of waste. We have developed a process of collecting and re-mixing this by-product into what we call the Studio Process Clay Body - an ever-changing material mix that represents the active work in the studio at the time it was mixed. While working with a changing material represents challenges from a ceramic chemistry standpoint, it opens up opportunities to further push the limits of what we can divert from waste streams.

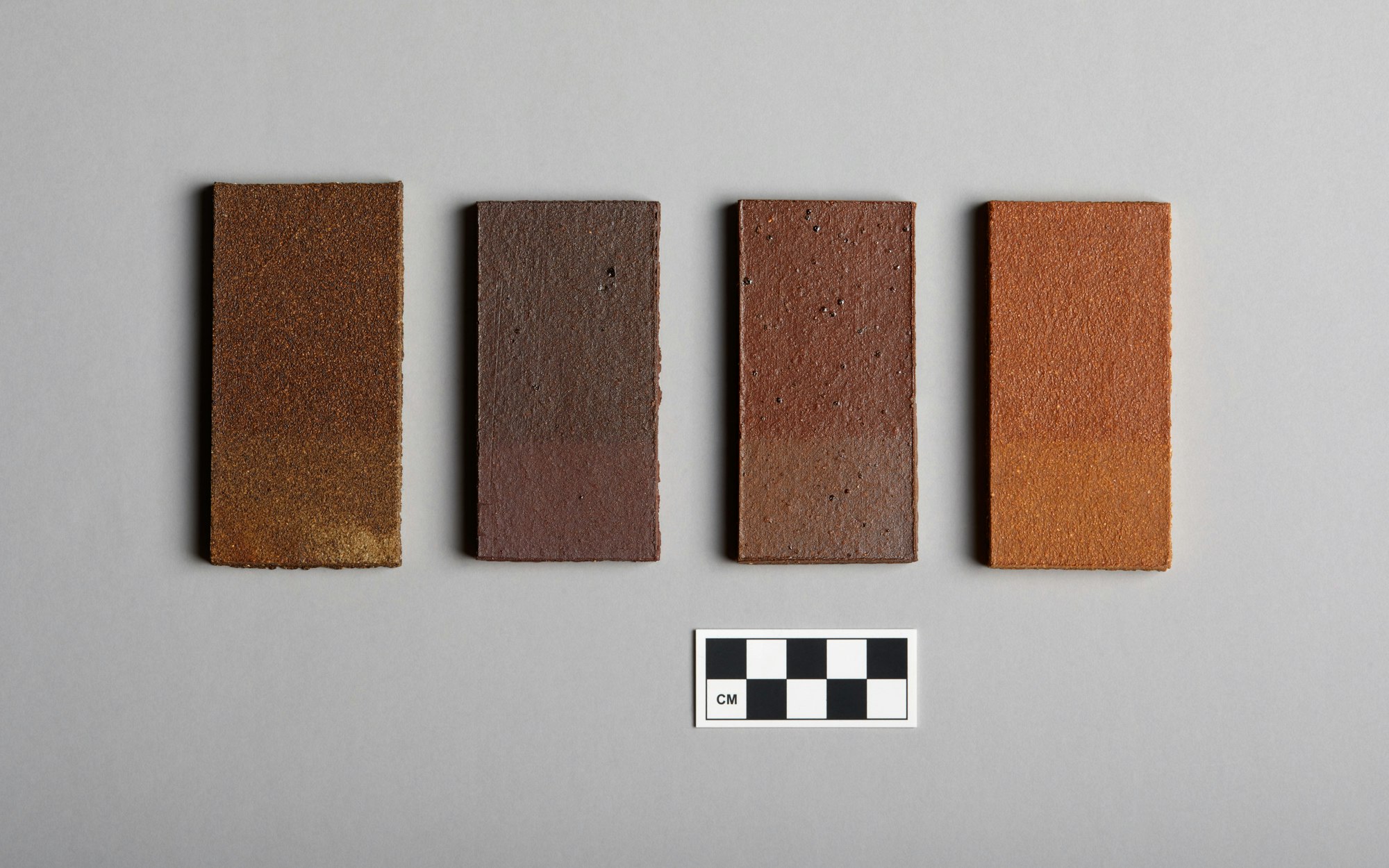

MATERIAL WASHES

Not strictly a waste material but rather a finishing technique that we can apply to waste to develop different material surfaces. These test tiles were treated with a mix of materials that cause the surface to reveal some of the inherent qualities of the clay. There is an inherent beauty to the materials we use and the term waste feels like a poor fit to describe the value and opportunity that still exists within these offcuts. Lately, we’ve been talking a lot about the patina of labour and how we might elevate the inherent properties of these processed materials.